Unlocking Efficiency and Savings with Pyrotec PackMedia Solutions

In an increasingly competitive world, businesses are always looking for ways to add value, stand out, and maximise returns. In the field of packaging, the

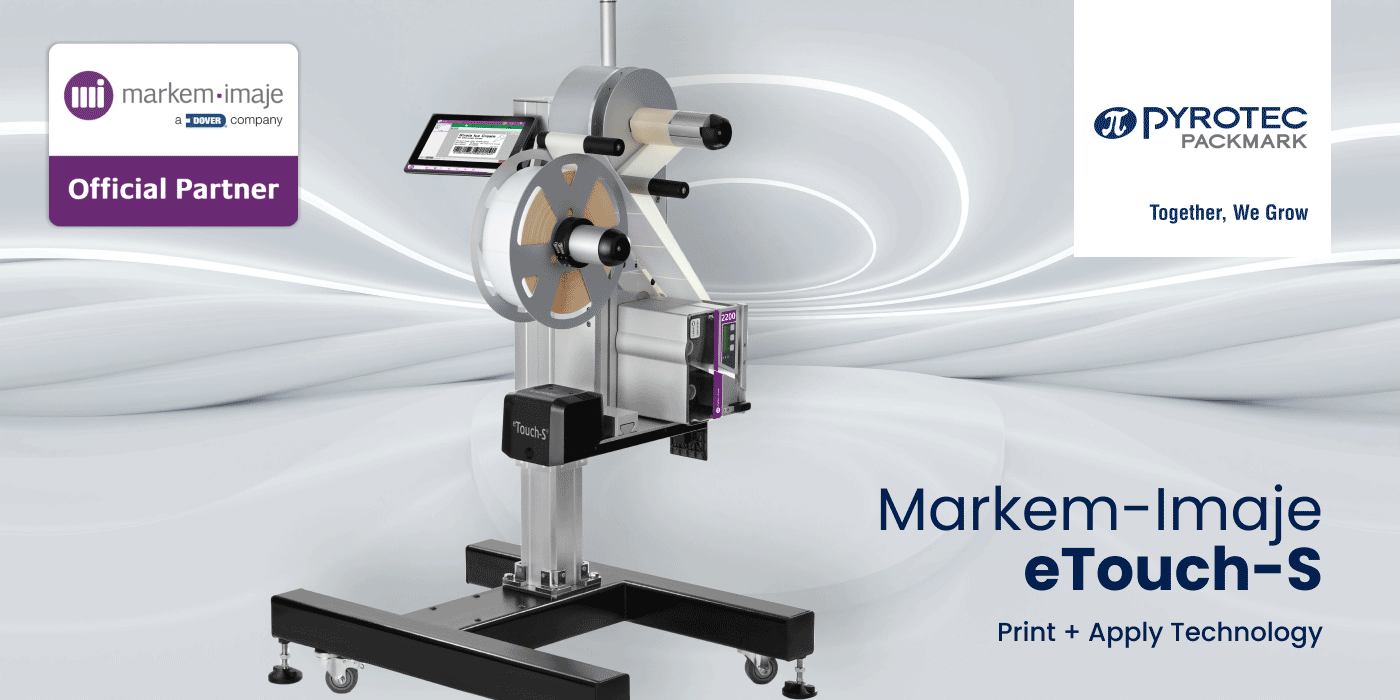

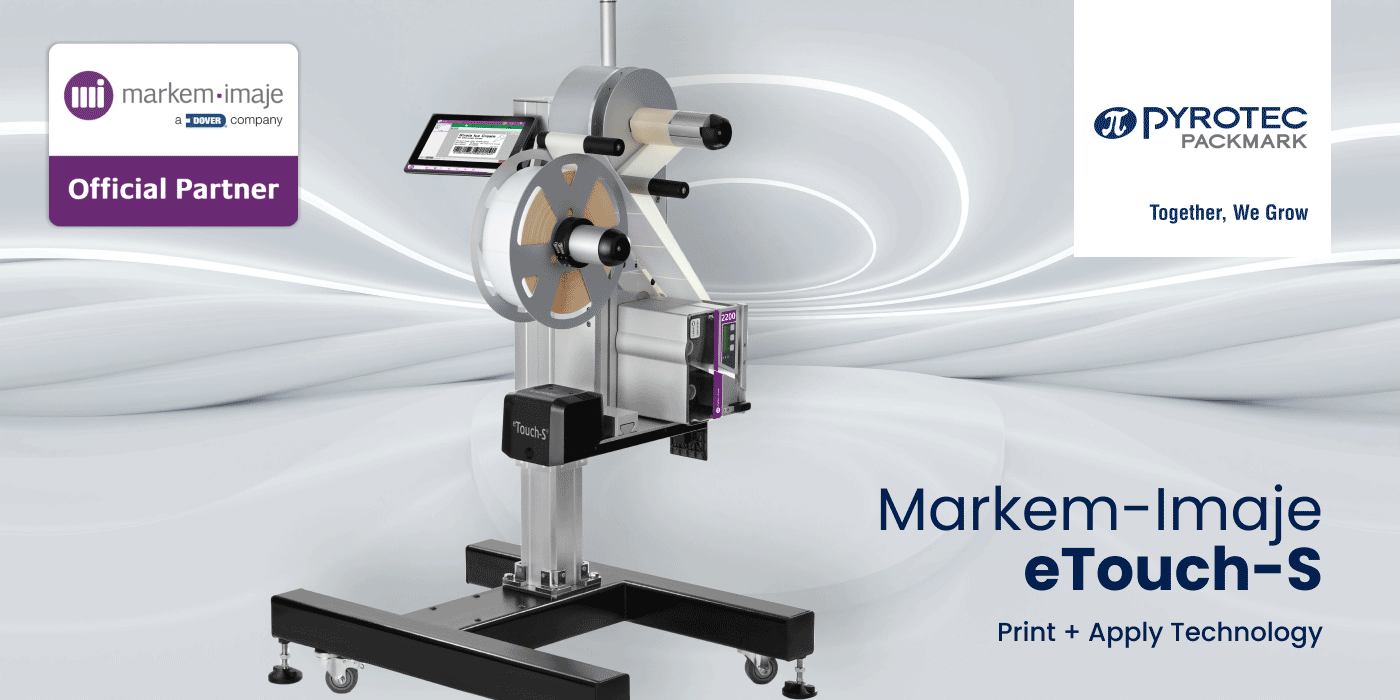

For factories requiring accurate case and pack labelling operations with minimal demand on factory resources – the eTouch-S Applicator, just launched with Pyrotec Packmark, ensures manufacturers fully comply with labelling standards without the need to regulate production throughput, change existing production methods, or install expensive additional pack control.

Unlike competitors’ equipment, the eTouch-S from Markem-Imaje – locally available from Pyrotec PackMark – accommodates high production speeds of up to 150 packs per minute (ppm) with pinpoint label accuracy. In addition, it complies with EN415-10 safety standards and offers completely unhindered operation without additional safety measures, regardless of application type and installation constraints.

With its proprietary design and patented technology, the eTouch-S Applicator is developed from the ground up, focusing on reducing manufacturers’ environmental impact. The eTouch-S removes the need for plant air without impacting supply chain traceability or increasing the risk of retailer fines for returned cases.

The innovative eTouch-S has built-in artificial intelligence (AI) that ensures labels are applied to an exacting standard on every pack at the highest production speeds. The Applicator’s unique SoftTouch technology offers complete movement control and application monitoring in conjunction with pack sensing that allows application without unnecessary force and the ability to detect any variation in pack positioning automatically. An optional Advanced Trigger Sensor (ATS) allows label packs with infinitely variable distances and speeds with constant label placement without the requirement for operational intervention or complex line integration.

“The eTouch-S is a truly intelligent, high-performance print and applies system,” notes Mike Kirk, Print and Apply Product Marketing Manager at Markem-Imaje.

“It’s a game-changer for customers looking for a safe, fast, durable, and simple solution, all while reducing downtime. The eTouch-S Applicator is ideal for manufacturers who want full labelling standards compliance and eliminate the need for regulating production throughput, changing existing production methods, or for expensive additional pack control.”

Designed with reliability in mind, the eTouch-S significantly reduces maintenance requirements thanks to its minimal moving parts. Efficient design allows for lower print speeds at higher throughput regardless of the data complexity or content, reducing machine burden and decreasing wear and total cost of ownership.

The eTouch-S includes all the enhanced features of Markem-Imaje’s 2200 Series, making the overall solution extremely easy to use, efficient and reliable. All models in the 2200 Series offer an intuitive user interface and a simple media path, allowing operators to replenish label and ribbon rolls in less than 40 seconds. The in-built auto-change/tandem functionality means that should a 2200 Series go offline, a second labeller will immediately take over the task to eliminate downtime associated with media changes.

Did you know?

To simplify your product range, the 2200 eTouch-S print and apply applicators can replace all current linear tamp applicators.

Until now, the four most common types of print and applications include:

Give us a call to discuss your end-of-line print and apply needs.

In an increasingly competitive world, businesses are always looking for ways to add value, stand out, and maximise returns. In the field of packaging, the

As technology advances, so do how we print and code our products. In particular, the laser coder has revolutionized how we approach industrial coding solutions,

In a rapidly evolving industry such as the nutraceutical market, product labelling stands as a crucial touchpoint between businesses and consumers. Premium labels aren’t just

| Cookie | Duration | Description |

|---|---|---|

| bcookie | 2 years | This cookie is set by linkedIn. The purpose of the cookie is to enable LinkedIn functionalities on the page. |

| lang | session | This cookie is used to store the language preferences of a user to serve up content in that stored language the next time user visit the website. |

| lidc | 1 day | This cookie is set by LinkedIn and used for routing. |

| mailchimp_landing_site | 1 month | The cookie is set by the email marketing service MailChimp. |

| Cookie | Duration | Description |

|---|---|---|

| YSC | session | This cookies is set by Youtube and is used to track the views of embedded videos. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | This cookie is installed by Google Analytics. The cookie is used to calculate visitor, session, campaign data and keep track of site usage for the site's analytics report. The cookies store information anonymously and assign a randomly generated number to identify unique visitors. |

| _gat_UA-80349225-14 | 1 minute | This is a pattern type cookie set by Google Analytics, where the pattern element on the name contains the unique identity number of the account or website it relates to. It appears to be a variation of the _gat cookie which is used to limit the amount of data recorded by Google on high traffic volume websites. |

| _gcl_au | 3 months | This cookie is used by Google Analytics to understand user interaction with the website. |

| _gid | 1 day | This cookie is installed by Google Analytics. The cookie is used to store information of how visitors use a website and helps in creating an analytics report of how the website is doing. The data collected including the number visitors, the source where they have come from, and the pages visted in an anonymous form. |

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | This cookie is set by Facebook to deliver advertisement when they are on Facebook or a digital platform powered by Facebook advertising after visiting this website. |

| bscookie | 2 years | This cookie is a browser ID cookie set by Linked share Buttons and ad tags. |

| fr | 3 months | The cookie is set by Facebook to show relevant advertisments to the users and measure and improve the advertisements. The cookie also tracks the behavior of the user across the web on sites that have Facebook pixel or Facebook social plugin. |

| IDE | 1 year 24 days | Used by Google DoubleClick and stores information about how the user uses the website and any other advertisement before visiting the website. This is used to present users with ads that are relevant to them according to the user profile. |

| test_cookie | 15 minutes | This cookie is set by doubleclick.net. The purpose of the cookie is to determine if the user's browser supports cookies. |

| VISITOR_INFO1_LIVE | 5 months 27 days | This cookie is set by Youtube. Used to track the information of the embedded YouTube videos on a website. |

| Cookie | Duration | Description |

|---|---|---|

| _ga_0B0QBQE3FJ | 2 years | No description |

| _gat_gtag_UA_80349225_14 | 1 minute | No description |

| AnalyticsSyncHistory | 1 month | No description |

| CONSENT | 16 years 6 months 21 days 16 hours | No description |

| cookielawinfo-checkbox-functional | 1 year | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-others | 1 year | No description |

| cookies.js | session | No description |

| li_gc | 2 years | No description |

| UserMatchHistory | 1 month | Linkedin - Used to track visitors on multiple websites, in order to present relevant advertisement based on the visitor's preferences. |