Unlocking Efficiency and Savings with Pyrotec PackMedia Solutions

In an increasingly competitive world, businesses are always looking for ways to add value, stand out, and maximise returns. In the field of packaging, the

It’s no secret that the beverage industry is wrapped up in quite a lot of regulations, particularly with things like labelling and packaging. It’s not just about ticking boxes for regulatory compliance – it’s also about keeping customers in the loop with straightforward, trustworthy product information. We get this level of transparency by paying close attention to beverage coding and labelling. This step is crucial for tracking, quality control, and keeping a handle on the supply chain.

However, simply sticking to rules isn’t the full story. The real hero behind the scenes is the application of good manufacturing practices, or GMPs, which ensure your codes and labels are top-notch quality all the time. As we dive deeper into this topic, we’ll dissect the importance of beverage labelling regulations and explore how transparency and sustainability are impacting the industry. Let’s unravel the fascinating journey your drinks take before they wind up in the hands of consumers.

The importance of beverage labelling regulations

Beverage labelling regulations are key in ensuring safety and helping consumers make smart buying decisions. There’re local and international rules that dictate how drinks should be labelled, providing all the need-to-knows – ingredients, nutrition, allergens, potential health risks – right on the product as is the case with the Food and Drug Administration (FDA) in the U.S. and the Food Safety and Standards Authority of India (FSSAI).

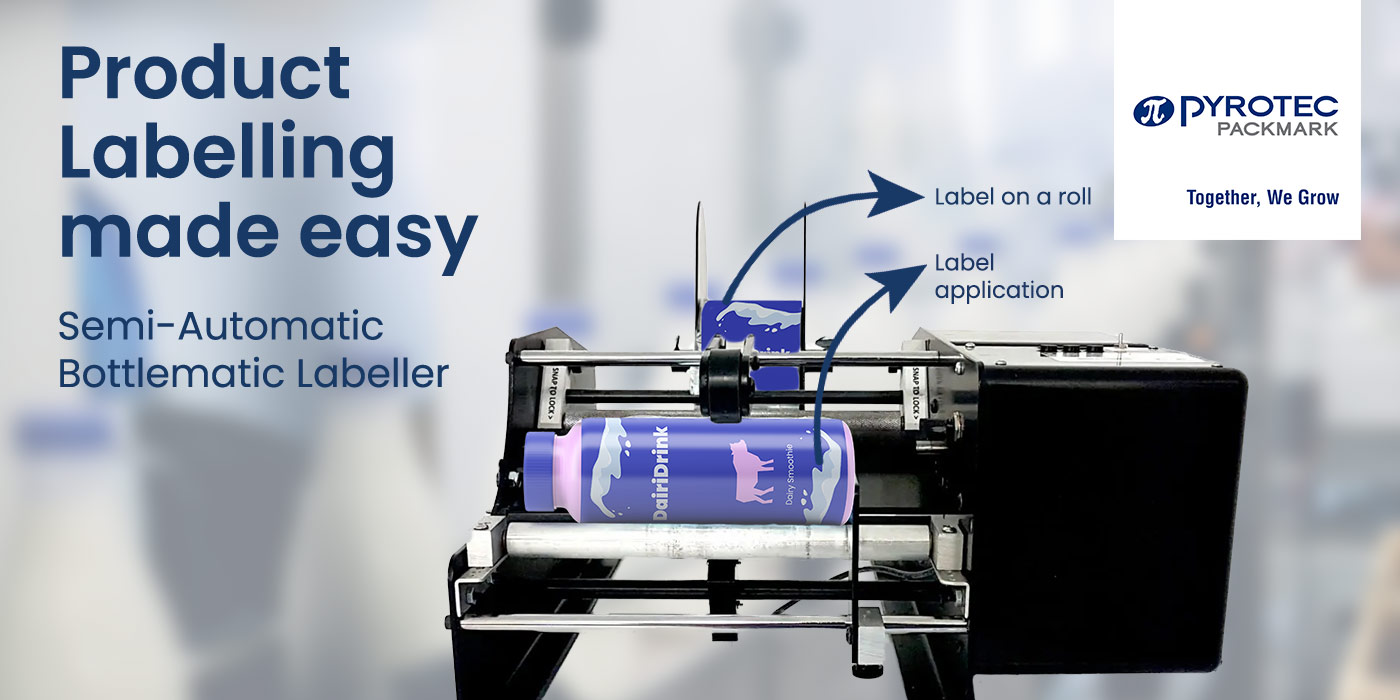

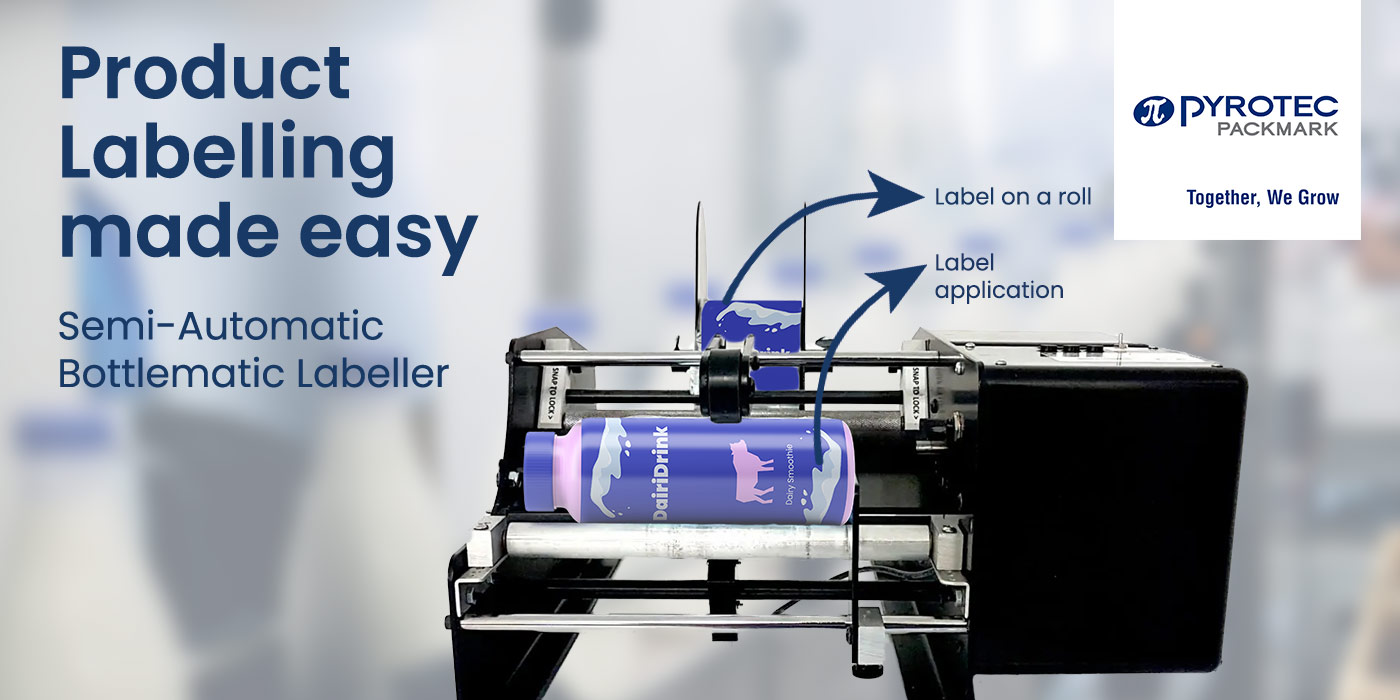

This is where coders and labellers like Bottle-Matic and ALline Labelling Systems come in handy. They are ideal for meeting labelling requirements. Product labelling and precise coding play a pivotal role in the beverage industry; they ensure the following:

The Influence of label transparency and Sustainability on consumer choice

People are getting savvy about what they’re eating and drinking these days. It’s not just about taste and convenience anymore. Everyone wants the lowdown on their drink labels – therefore, your company needs to help retailers meet this consumer demand.

And it doesn’t stop at health. Sustainability is no longer just a buzzword; it is now a vital part of core business values. Brands that can show they are playing their part toward a sustainable future are the ones consumers gravitate to. To ensure they grow with their customers, retailers and brands have stepped up their game too. Goodbye, plastic bottles; hello, water cans! So, you need a labeller that is versatile enough to improve the production line and help your clients meet the demands of end-user consumers, like one of these Primary Coders.

So, ensure you stay on top of your product coding game with technology that continues to change the beverage industry, such as the Anser U2 Pro S, allowing you to achieve higher levels of efficiency, accuracy, and productivity in your production processes.

We are your trusted partner in the labelling industry. Reach out to our team at packmark@pyrotec.co.za for your future-forward factory.

In an increasingly competitive world, businesses are always looking for ways to add value, stand out, and maximise returns. In the field of packaging, the

As technology advances, so do how we print and code our products. In particular, the laser coder has revolutionized how we approach industrial coding solutions,

In a rapidly evolving industry such as the nutraceutical market, product labelling stands as a crucial touchpoint between businesses and consumers. Premium labels aren’t just

| Cookie | Duration | Description |

|---|---|---|

| bcookie | 2 years | This cookie is set by linkedIn. The purpose of the cookie is to enable LinkedIn functionalities on the page. |

| lang | session | This cookie is used to store the language preferences of a user to serve up content in that stored language the next time user visit the website. |

| lidc | 1 day | This cookie is set by LinkedIn and used for routing. |

| mailchimp_landing_site | 1 month | The cookie is set by the email marketing service MailChimp. |

| Cookie | Duration | Description |

|---|---|---|

| YSC | session | This cookies is set by Youtube and is used to track the views of embedded videos. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | This cookie is installed by Google Analytics. The cookie is used to calculate visitor, session, campaign data and keep track of site usage for the site's analytics report. The cookies store information anonymously and assign a randomly generated number to identify unique visitors. |

| _gat_UA-80349225-14 | 1 minute | This is a pattern type cookie set by Google Analytics, where the pattern element on the name contains the unique identity number of the account or website it relates to. It appears to be a variation of the _gat cookie which is used to limit the amount of data recorded by Google on high traffic volume websites. |

| _gcl_au | 3 months | This cookie is used by Google Analytics to understand user interaction with the website. |

| _gid | 1 day | This cookie is installed by Google Analytics. The cookie is used to store information of how visitors use a website and helps in creating an analytics report of how the website is doing. The data collected including the number visitors, the source where they have come from, and the pages visted in an anonymous form. |

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | This cookie is set by Facebook to deliver advertisement when they are on Facebook or a digital platform powered by Facebook advertising after visiting this website. |

| bscookie | 2 years | This cookie is a browser ID cookie set by Linked share Buttons and ad tags. |

| fr | 3 months | The cookie is set by Facebook to show relevant advertisments to the users and measure and improve the advertisements. The cookie also tracks the behavior of the user across the web on sites that have Facebook pixel or Facebook social plugin. |

| IDE | 1 year 24 days | Used by Google DoubleClick and stores information about how the user uses the website and any other advertisement before visiting the website. This is used to present users with ads that are relevant to them according to the user profile. |

| test_cookie | 15 minutes | This cookie is set by doubleclick.net. The purpose of the cookie is to determine if the user's browser supports cookies. |

| VISITOR_INFO1_LIVE | 5 months 27 days | This cookie is set by Youtube. Used to track the information of the embedded YouTube videos on a website. |

| Cookie | Duration | Description |

|---|---|---|

| _ga_0B0QBQE3FJ | 2 years | No description |

| _gat_gtag_UA_80349225_14 | 1 minute | No description |

| AnalyticsSyncHistory | 1 month | No description |

| CONSENT | 16 years 6 months 21 days 16 hours | No description |

| cookielawinfo-checkbox-functional | 1 year | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-others | 1 year | No description |

| cookies.js | session | No description |

| li_gc | 2 years | No description |

| UserMatchHistory | 1 month | Linkedin - Used to track visitors on multiple websites, in order to present relevant advertisement based on the visitor's preferences. |