Description

The incorporation of the very latest in control technology enables ‘Sirius’ to handle a wide variety of product and label shapes making it the most versatile, user-friendly, efficient and highly accurate labelling system. Packed with the latest technology for even greater production line benefits, ‘Sirius’ has been designed to meet the most stringent GMP requirements as well as addressing MTBF (Mean Time Between Failure) and MTTR (Mean Time To Repair) needs.

Enhanced Features

- The motion control system provides increased labelling accuracy coupled with absolute speed matching to cope with variable speed demands of today’s packaging lines.

- Enhanced control system incorporating a single touch screen user interface provides a very high level of user diagnostics.

- The unique software enables quick set-up times between product changeover and is self-monitoring to provide optimum reliability.

- This reduces the skill level required for operation and maintenance.

- Increased cabinet space allows for greater flexibility for future upgrades.

- Fully-integrated inspection systems to identify label and/or overprint presence. Barcode readability is available and easily incorporated. Also available is the integration of a vision system capable of identifying label position on the product plus the correct lot/expiration data.

- Modularised transmission system utilising the latest technology ensures that the Sirius provides the optimum level of flexibility and reliability for all current and future labelling requirements.

- These next generation of ‘Harland Sirius’ features are also incorporated in the Tamper Evident (TE), Twin Side Belt (TSB), Top/Bottom and Vertical roller Stabiliser (VRS) labellers.

Technical Specifications

- Base unit

- Stainless steel unit, available with 1 or 2 label stations.

- Infeed unit

- Single scroll, twin-scroll, infeed wheel, orientation units for aligning ovals.

- Label Head

- Label head speeds up to 28.5m/min.

- Stepper motor-driven motion-controlled.

- Stabiliser

- Horizontally mounted 935mm long servo-driven unit.

- Conveyor – 2438 mm long, 82.5mm.

- Delryn slatband.

- Finishing units

- non-driven and driven wipedown rollers, wraparound unit, walking beam.

- Overprint unit

- Hot foil, deboss, thermal transfer, inkjet, and laser coders.

- Ancillary Equipment

- a wide range is available including – product and label counters, infeed/outfeed monitoring controls and pharmaceutical security systems.

- Capacities

- as standard.

- Speed

- up to 300 ppm (subject to application).

Product:

- Max – Minimum Height 350 mm – 20 mm.

- Max – Minimum Width 200 mm – 15 mm.

- Max diameter with full wrap-around – 100 mm.

- Electricity Supply – 220V/240V single-phase AC, 50/60Hz. Special electrical options are available on request.

- Air Supply – air required for some overprinters and security systems.

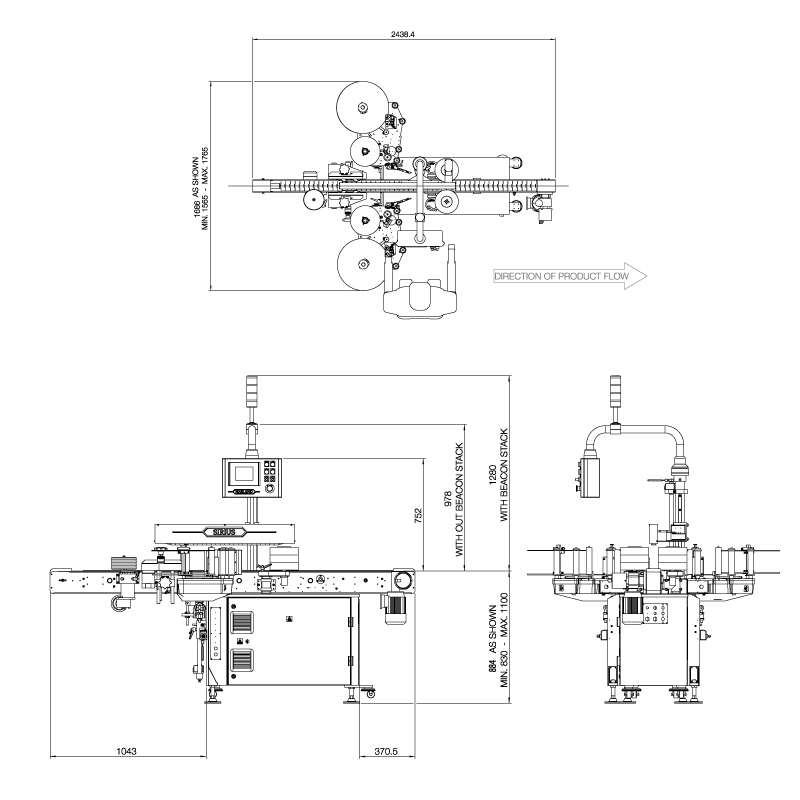

- Dimensions – See diagram.

- Weight – as standard 320 kg.

Label:

- Max – Minimum Web Width 155 mm – 13 mm.

- Max – Minimum Label Length 330 mm – 10 mm.

- Max reel OD 400 mm.

- Nominal reel ID 76 mm.

NB: 265 mm web width available as an option at extra cost. Increased cabinet space allows for greater flexibility for future upgrades.