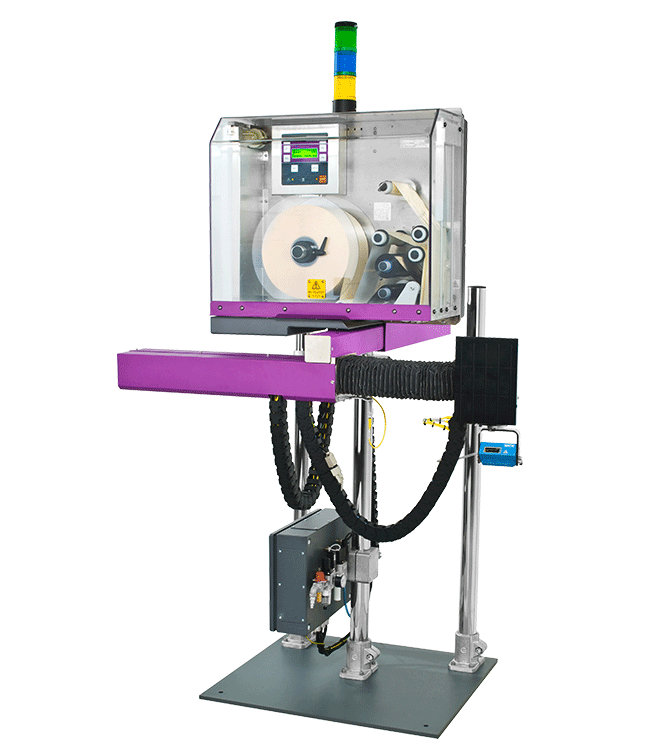

Description

Print Features

- Print methods: Thermal transfer or direct thermal

- Maximum print width 152 mm

- Standard application pad 150 x 210 mm (minimum label size 75 x 105 mm)

- Print resolution/speed 200 dpi 150 mm/sec

- Up to 120 pallets per hour

- Application rate two labels in 14 seconds (front and side)

- Flexible tamp application front, front/side, side, front/side/rear, rear/side, rear

- Active pallet detection for uneven or variable pack configurations

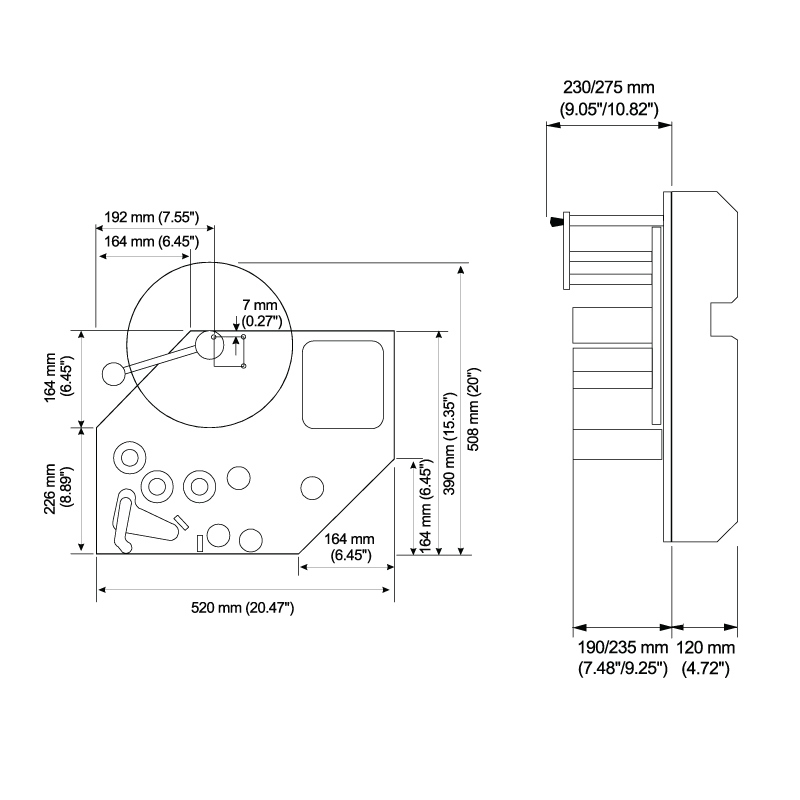

- Applicator stroke 2 axis 500 x 500 mm or 500 x 750 mm

- Flexible installation options with machine hand and multi-position applicator head

- Built-in real-time clock

- All major barcodes supported

- Logos and images supported

Accessories

- Customer application pads

- Visual alarm beacons

- Label verification scanner

- Barcode reader

- Environmental dust cover

- Active heated environmental cover (-15 ºC to 40 ºC)

- Ethernet connection

- Automated height adjustment for double or stacked pallets

- Fully integrated software solutions

- Windows-based label design package (CoLOS®)