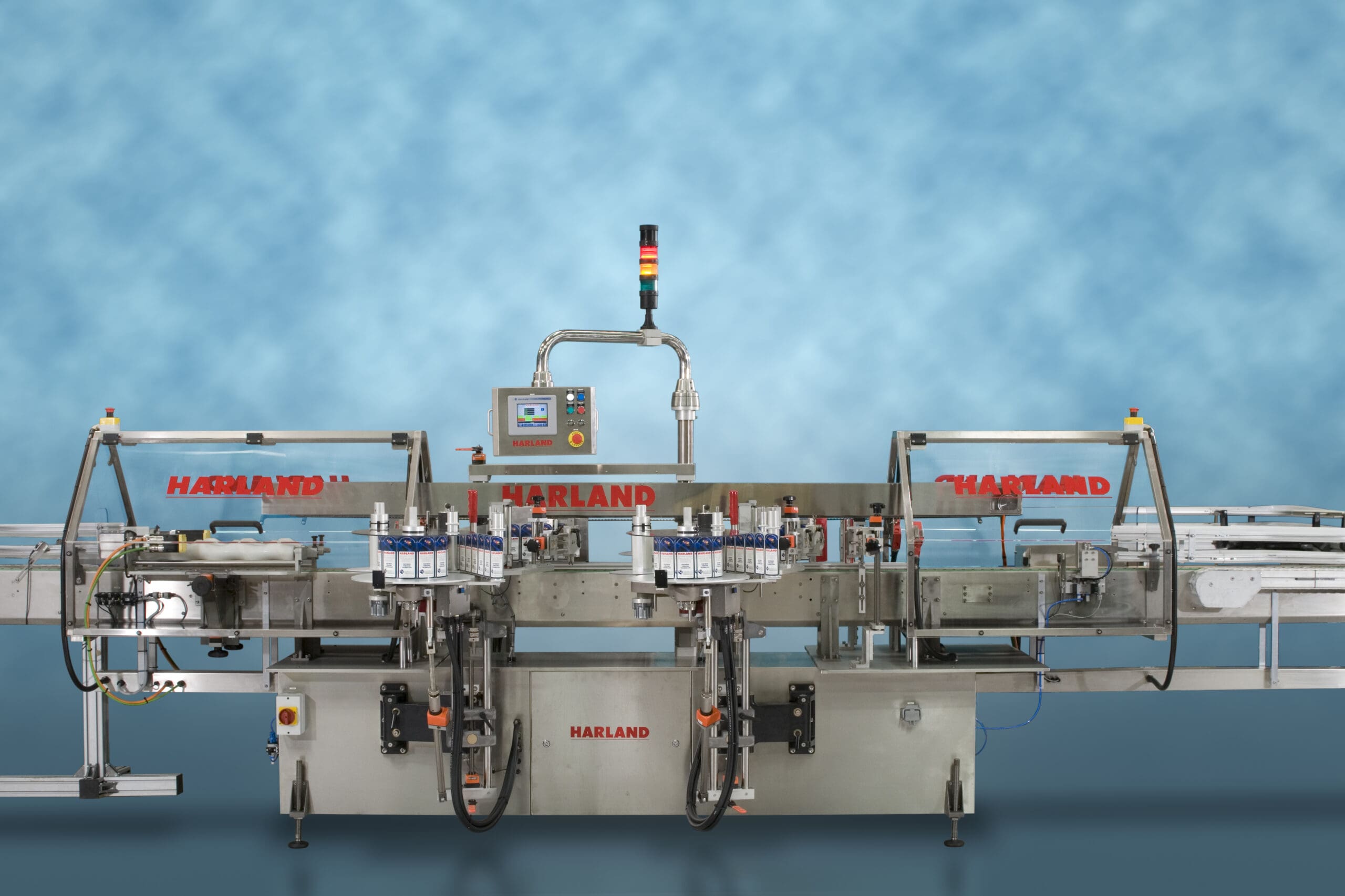

Description

Technical Specifications

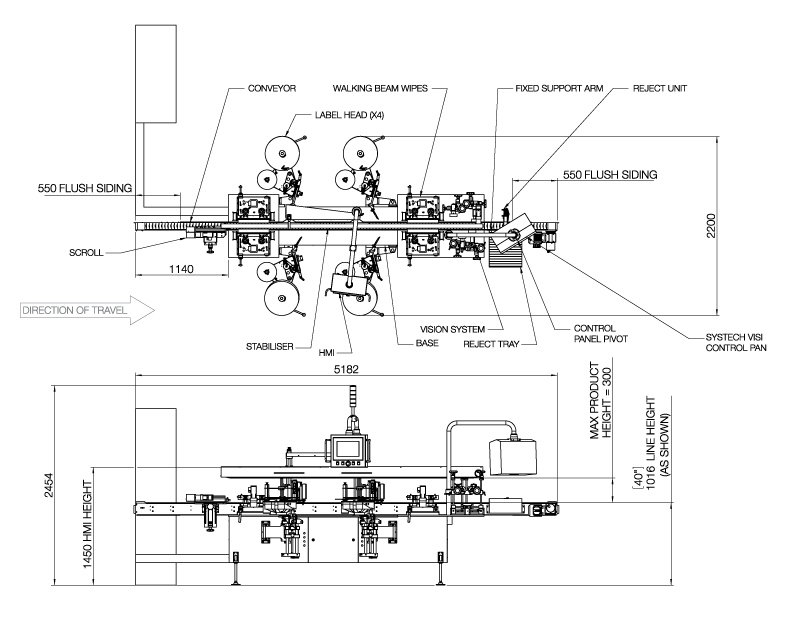

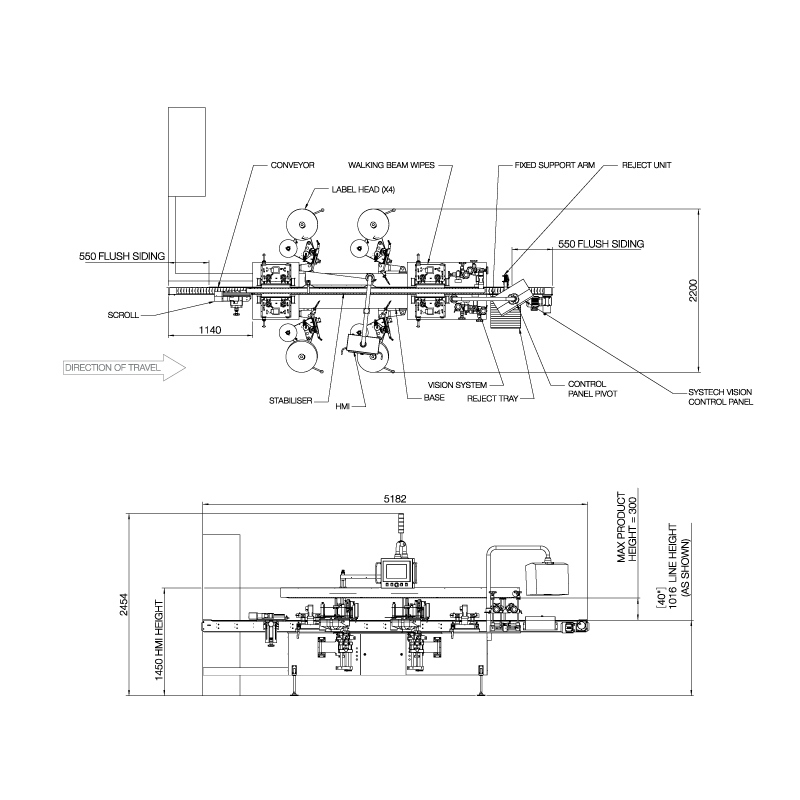

- Base unit – Stainless steel unit, available with 2 or 4 label stations.

- Infeed unit – Single scroll, twin-scroll, infeed wheel, and/or centering units.

- Label Head – Motion controlled with stepper and servo motor options.

- Stabilizer – Horizontally mounted servo-driven unit.

- Conveyor – 4500 mm-5000 mm long, 82.5 mm Delryn slatband.

- Finishing units – Servo-driven walking beam, powered wipedown rollers.

- Overprint unit – Hot foil, deboss, thermal transfer, inkjet, and laser coders.

- Ancillary Equipment – a wide range is available including – product and label counters, infeed/outfeed monitoring controls. Pharmaceutical security system. Integral vision system with a single point interface.

- Capacities – as standard.

- Speed – up to 250 ppm (subject to application).

- Product:

- Max – Minimum Height 425 mm – 20 mm.

- Max – Minimum Width 100 mm – 15 mm.

- Label:

- Max – Minimum Web Width 155 mm – 265 mm.

- Max – Minimum Label Length 330 mm – 10 mm.

- Max reel OD – 400 mm.

- nominal reel ID – 76 mm.

- Electrical Supply – 220/240V Single Phase AC, 50/60Hz subject to validation.

- Weight – as standard 700 kg.